CRITICAL PATH ANALYSIS, PERT, GANTT CHART - Time and Motion

- Jun 9, 2017

- 1 min read

KEY RESULTS AREA

To prevent

Idle time or waiting time of Staff – unproductive cost

Intermittent (loss of momentum) – inefficient cost

Particularly in Foods, Work In Process (WIP) Goods may not be fresh

and lead to rejection

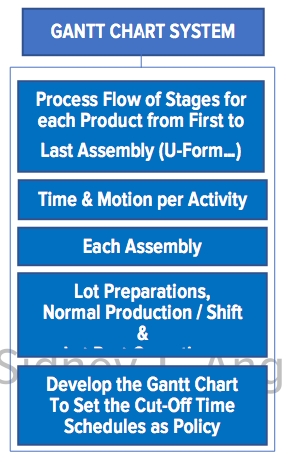

Gantt Chart Schedule is base on ...

Lot Preparation and Post Operations

Batch Cycle Time per Assembly multiplied by numbers of batches per shift. Also total numbers of Batches and Shifts per Lot

Time and Motion shall be based on Proper Working Table Lay-Out including Height & other activities related. Only hand movement for Quality with Quantity Parameter Outputs. Covers Piling & Bulk Handling Systems.

Apply to Assembly Line, Inter-Assembly Line and finally to Partial Transfer to Warehouse Finish Goods via Batch Bulk Handling (Pile Standard) for Handling Cost per Batch

Comments